Choosing enterprise software isn’t only a technical decision; it is a business bet that shapes your costs, agility, and customer experience for years. When teams debate custom ERP software versus a ready-made, off-the-shelf package, they are really weighing control against convenience, uniqueness against standardisation, and long-term fit against short-term speed.

In this guide, we’ll compare both approaches with practical criteria you can take to your next leadership meeting. You’ll find pros, cons, and a sensible middle path, plus a small case study drawn from a typical Indian mid-market manufacturer. By the end, you’ll have a checklist to help you pick the right direction with confidence.

What Do We Mean by Custom vs Ready-Made?

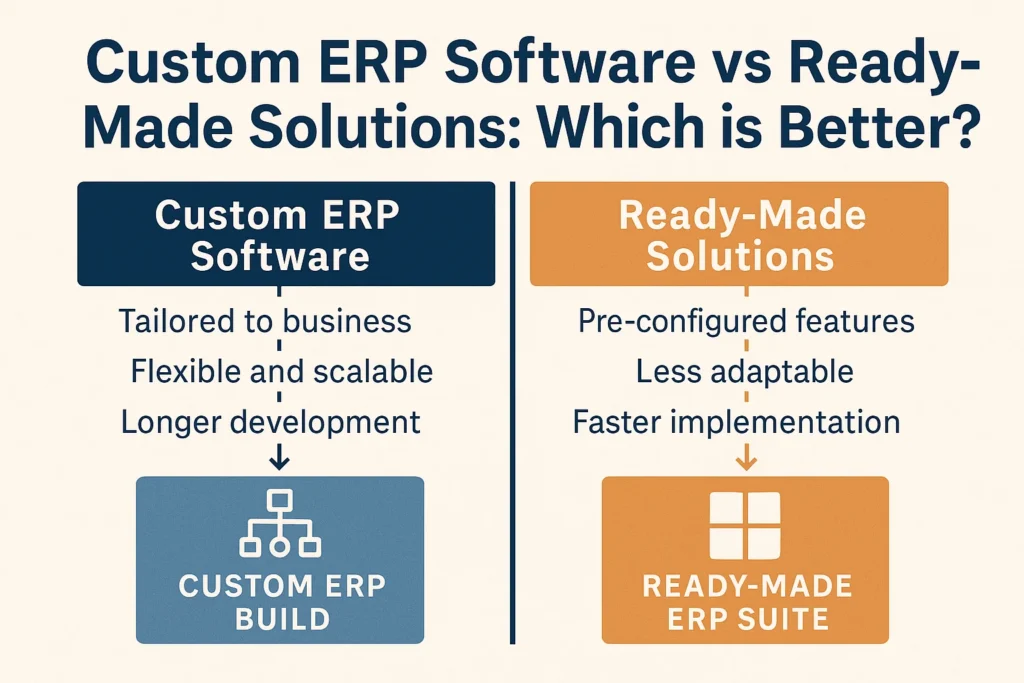

Let’s define terms clearly. A custom ERP is purpose-built around your processes, usually by a software partner or in-house team using a framework or low-code platform. A ready-made ERP is a commercial product with prebuilt modules for finance, inventory, sales, manufacturing, HR, and more. You implement it largely as designed, configuring and extending where allowed.

Why does the distinction matter? Because it changes who adapts to whom. With a custom build, the software bends to your process. With a product, your process bends to the software. Neither is inherently “right”; the question is where your competitive advantage sits—process uniqueness or operational discipline.

- Choose custom when your workflows are truly differentiating and stable.

- Choose ready-made when you want proven best practices and faster rollout.

- Choose hybrid when you need a product core plus targeted custom apps.

Rule of thumb: the rarer your processes and the clearer your long-term roadmap, the stronger the case for custom. The more standard your operations and the tighter your timeline, the stronger the case for ready-made.

Total Cost of Ownership in ERP Software

Total cost of ownership (TCO) looks beyond sticker price. Include licenses, cloud hosting or on-prem infrastructure, implementation fees, customisation, integration, data migration, training, change management, ongoing support, and periodic upgrades. Both paths can be economical—or expensive—depending on scope discipline.

Ready-made ERPs often show lower upfront cost because you buy subscriptions and add implementation services. But heavy customisation inside a product can push costs up and complicate upgrades. Custom ERP may start higher due to design and build, yet can be cheaper over five years if it avoids unused modules and fits like a glove.

| Cost Element | Custom ERP | Ready-Made ERP |

|---|---|---|

| Licensing | None or platform fees | Per user/module |

| Implementation | Design + build | Configure + migrate |

| Customisation | Native, unlimited | Limited by vendor |

| Upgrades | On your schedule | Vendor cadence |

| Support | In-house/partner | Vendor/partner |

To compare apples to apples, model TCO across three horizons: 12 months (implementation), 36 months (stabilisation), and 60 months (maturity). Assign probabilities to risks—scope creep, staff churn, vendor lock-in—and add contingency. A transparent TCO model prevents surprises later.

Implementation Speed, Risk, and Change Management

Speed matters. Ready-made suites shine here because business processes, reports, and permissions are pre-built. If you adopt their defaults, go-live can happen within weeks to a few months, especially for greenfield operations.

Custom ERP software typically takes longer. You will map processes, design data models, build integrations, develop screens and workflows, and test thoroughly. However, the extra time is not waste if it removes workarounds and double entry that persist for years in a misfit product.

- Time to first value: ready-made wins.

- Time to complete fit: custom often wins.

- Change management load: equal, but different—training versus elicitation.

Consider risk. Product implementations risk “customising the product until it behaves like a custom build,” which undermines upgrades. Custom builds risk under-scoped requirements and key-person dependency. Mitigate both with staged releases, automated tests, and an empowered product owner from the business.

Scalability and Flexibility in ERP Software

Growth brings new plants, channels, SKUs, tax regimes, and partners. Can your ERP model that complexity without heroic effort? Ready-made platforms usually provide mature multi-company, multi-currency, and compliance features out of the box. They also benefit from vendor benchmarks and community add-ons.

Custom systems flex deeply in the areas you choose to invest. If your business model evolves—say you add direct-to-consumer alongside B2B—a custom order management flow can be extended faster than a rigid product module. The catch is you must budget engineering time, governance, and documentation so today’s shortcuts don’t become tomorrow’s bottlenecks.

- Plan scaling patterns: data volume, users, transactions per minute.

- Set SLOs for latency and availability.

- Adopt API-first integration so partners can plug in cleanly.

In short, flexibility is highest with custom, breadth is strongest with products, and a hybrid approach can give you both—product for the baseline, custom services for your secret sauce.

Security, Compliance, and Data Ownership

Security is non-negotiable. Reputable ready-made ERP vendors invest heavily in certifications, secure SDLC, and third-party audits. You inherit those controls, provided you configure them properly. Data residency and role-based access are usually first-class features.

With custom ERP, you control the stack, choose the cloud region, and set encryption, logging, and backups to your policy. That control is powerful but comes with responsibility: security expertise, regular penetration tests, and patch management cadence. For regulated sectors—pharma, BFSI, government—you must budget compliance from day one.

Data ownership deserves attention. Vendor lock-in is real when exports are proprietary, APIs are rate-limited, or workflows cannot be replicated. Insist on data export commitments, documented schemas, and migration tooling regardless of path.

Case Study: Boutique Manufacturer Chooses a Hybrid Path

Consider “Tara Textiles,” a 300-employee home-linen manufacturer in Coimbatore selling to retailers and online marketplaces. The team replaced spreadsheets and a legacy on-prem system with a cloud ERP for finance, inventory, and procurement. They kept product master and production scheduling custom because their dye-lot constraints and make-to-order batches were unique.

What happened? Within four months, they closed books in five days instead of twelve, stockouts dropped 18 percent, and purchase price variance became visible by vendor. Meanwhile, the custom planning module handled colour mixing rules, loom capacity, and rework loops that generic MRP could not capture without heavy hacks. Integration ran through event-driven APIs, so marketplace orders triggered production reservations instantly.

The lesson is not that hybrid is always best; it is that each capability belongs where it can deliver the most value with the least friction. Finance is standard—buy it. Your differentiator—build it. Integrate loosely so each side can evolve independently.

How to Decide: A Practical Checklist

Gather cross-functional leaders and score the following on a five-point scale. Higher scores favour custom; lower scores favour ready-made.

- Process uniqueness: Do our workflows create advantage customers will pay for?

- Process stability: Are those workflows stable for the next three to five years?

- Time pressure: Do we need a go-live in under six months?

- Budget certainty: Do we prefer predictable subscription costs?

- Talent capacity: Do we have or can we fund product and engineering skills?

- Compliance burden: Are we in a heavily regulated industry?

- Integration needs: How many systems must talk to the ERP reliably?

Plot the scores on a simple radar chart for your leadership team. If the picture leans toward speed, predictability, and broad features, a ready-made ERP is prudent. If it leans toward uniqueness, deep integration, and tight fit, custom or hybrid makes sense.

Vendor Ecosystem, Support, and Upgradability

Beyond features, consider the people and partners behind the platform. With ready-made suites, you gain an ecosystem of certified implementers, community forums, app marketplaces, and structured release notes. That velocity helps, but change is constant; plan regression testing for quarterly updates periodically.

Custom ERP success rests on your own operating model. You will choose the stack, the CI/CD pipeline, the monitoring tools, and the documentation standard. That freedom lets you prioritise what matters—say, automated tests for tax logic each April—but it introduces key-person risk if engineers move on. Reduce that risk by codifying architecture decisions, maintaining runbooks, and cross-training administrators and business super users.

Conclusion

So, which is better—custom ERP software or a ready-made solution? The honest answer is: it depends on where your value lives and how fast you must move. Ready-made brings speed, proven processes, and a community. Custom brings precision, differentiation, and control. A hybrid strategy, with a product core and targeted custom services, often gives Indian businesses the best of both worlds.

Anchor your decision in TCO over five years, not just first-year fees. Respect change management as a first-class workstream. Design for integration and data portability from day one to avoid lock-in. And remember: your ERP is not only a system of record—it is a system of work. Choose the path that lets your people do their best work with the least friction, and you will rarely go wrong.